- Model:EA6000VX

- Product:X-ray Fluorescence Analyzer

♦ High-speed Mapping

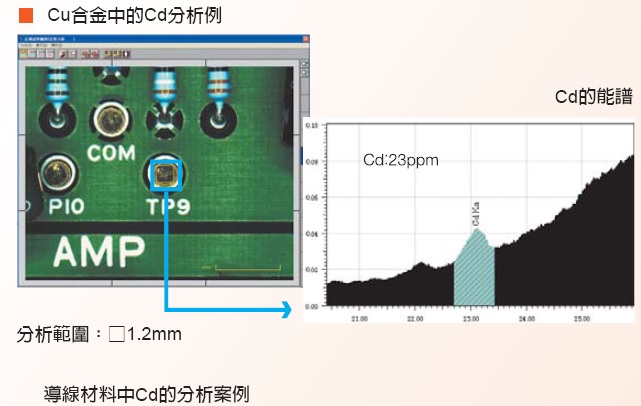

♦ Microscopic Area Analysis

♦ High Count Rate Detector (Vortex®)

♦ Helium purge optional

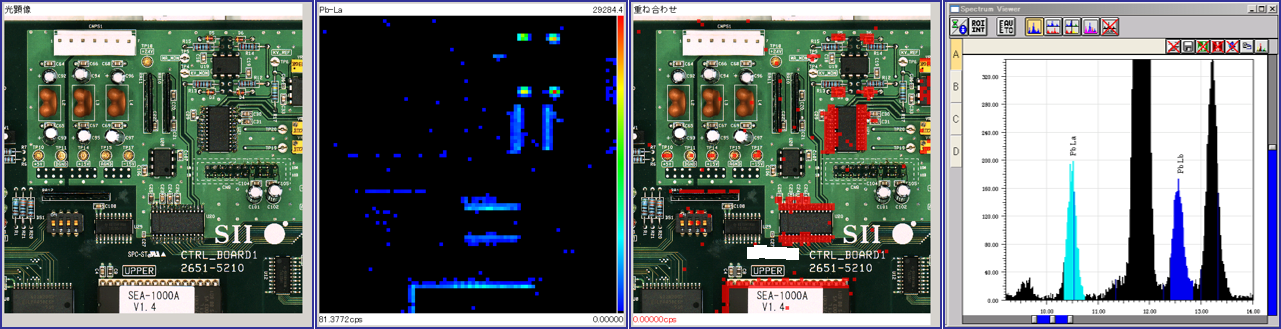

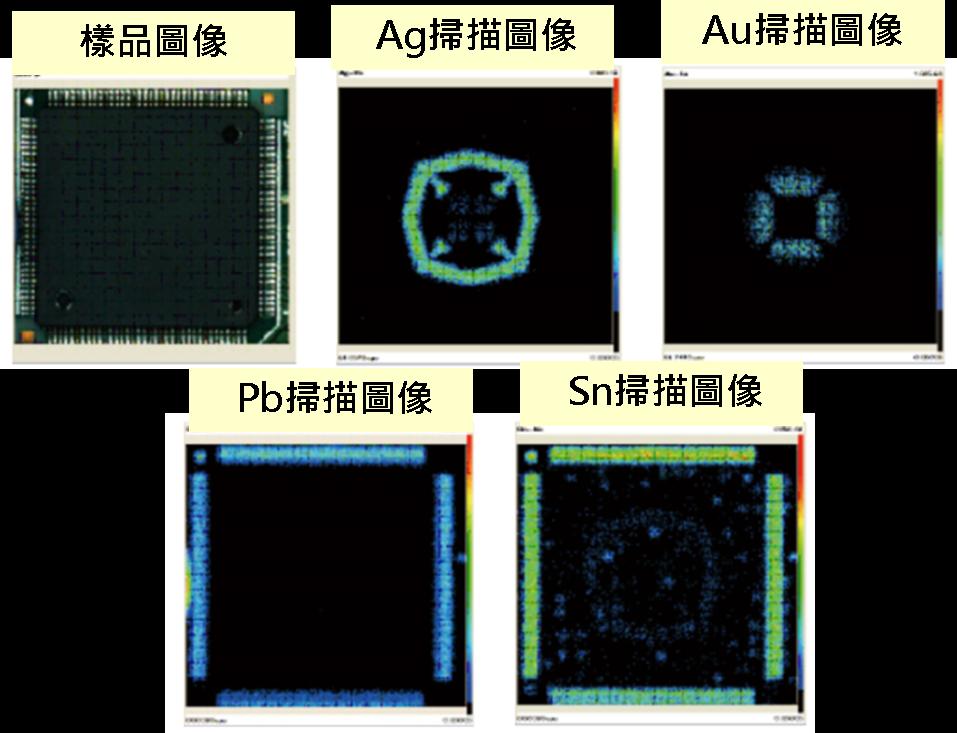

High-speed Mapping

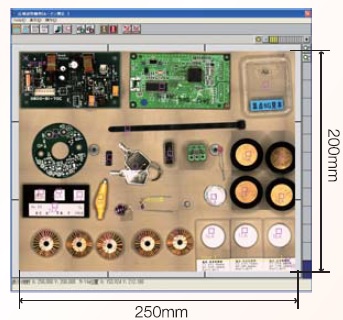

The high count rate Vortex detector (max. 150,000 cps) and the large stage that scans a max. 250 mm × 200 mm area provide high-speed mapping. For example, when mapping a 100 mm × 100 mm area, the EA6000VX can detect and specify the location of lead contained in the terminal of a mounting board in just a few minutes.

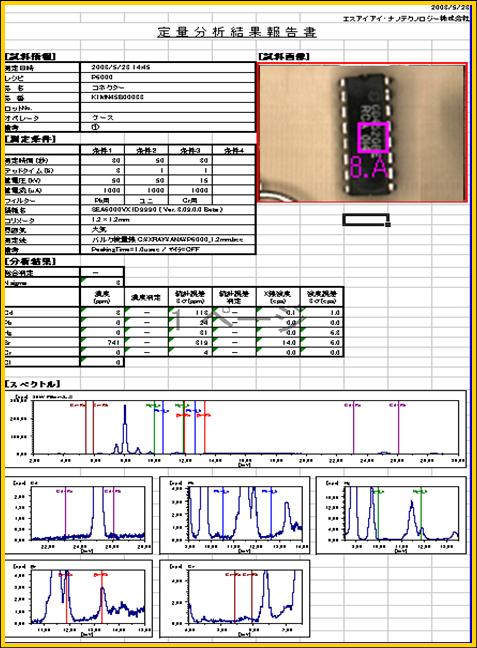

Continuous multi-point Measurements

With an auto-sampler, up to 500 points can be specified and continuously measured. Thus, measuring large samples can be performed with high throughput and minimal user intervention.

Microscopic Area Coating Thickness Measurements

The EA6000VX is capable of coating thickness measurements typical of the FT series including coating thickness measurement of ultra-thin Au films. Analysis of hazardous substances such as Pb in plating can be measured simultaneously with coating thickness measurements. For example, possibilities include composition measurement of hazardous substances in Pb-free solder plating, Sn plating of lead frames, and electroless Ni plating.

Light Element Measurement

The He Purge option enables the analysis of light elements starting with Na. The system purges with He only while making measurements, providing stable, cost-effective analysis.

See-through Mapping Function

Mapping images of various elements, such as Pb on boards, can be obtained without taking apart products or even knowing anything about the internal structure of laptop computers and cell phones, for example. By comparing the element mapping images obtained by penetrating X-rays, a great deal of information can be obtained about the structure and internal components.

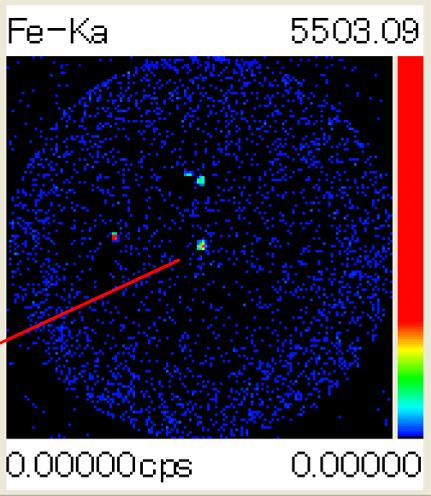

Contaminant Analysis

With its high-speed mapping function, the EA6000VX is able to detect and locate small metal contaminants in the tens of micrometers size range for a wide measurement area (at a maximum of 250 mm × 200 mm). Small or minute amount of contaminant contained in organic substances including resin, can be also detected.

Technologically Enhanced Operability -Auto Approach and Sample Collision Prevention Mechanism

Auto Approach Function measures the sample height and automatically adjusts the distance between sample and detector so that operator can easily measure samples with complicated shapes. In the case of manual operation, Sample Collision Prevention Mechanism prevents sample damages.

Standard reference materials for various environmental regulations (optional)

A variety of standard reference samples developed and manufactured in-house are available; those include not only for the RoHS restricted elements (Cd, Pb, Hg, Br, and Cr), but also for other elements such as chlorine (Cl), antimony (Sb) and tin (Sn) and so forth.

| Item | Specification |

|---|---|

| Origin | Japan |

| Elements | Na11 to U92 (when using helium purge option) |

| Sample type | Solid, Powder, Liquid |

| X-ray source | X-ray tube (Rh or W target) Voltage: 15 kV, 30 kV, 40 kV, 50 kV Current: 1 mA (10 μA to 1,000 μA variable) |

| X-ray irradiation direction | Top-down Irradiation |

| Detector | Vortex® (SDD) (Liquid nitrogen not required) |

| Analysis Area | Square 0.2 mm, 0.5 mm, 1.2 mm, 3 mm (automatic switching) |

| Sample imaging | High resolution CCD camera, 2 system |

| Filters | 6 mode automatic switching (including OFF) |

| Maximum sample size | 250(W)×200(D)×150(H) mm |

| Size | 750(W)×740(D)×783(H) mm |

| Weight | 160Kg |

| Software | X-ray Station

|

| Power usage | AC100~240 V (50/60Hz) / 400 VA |

| Classification | Title | Date |

|---|

LINE

LINE Facebook

Facebook