- Model:EA1400

- Product:X-ray Fluorescence Analyzer

♦ High sensitivity and high throughput

measurement

♦ Vacuum System and New SDD

♦ From RoHS control to an extensive range of

areas

The newly developed silicon drift detector (SDD)

For customers in such variety of application fields as process and quality control of cement or slags, failure analysis of abnormal spot, and inspection of foreign matter as well as RoHS inspection, the EA1400 delivers on reducing measurement time, simplifying the management of measurement results, reducing operational mistakes, and improving efficiency.

High sensitivity and high throughput measurement

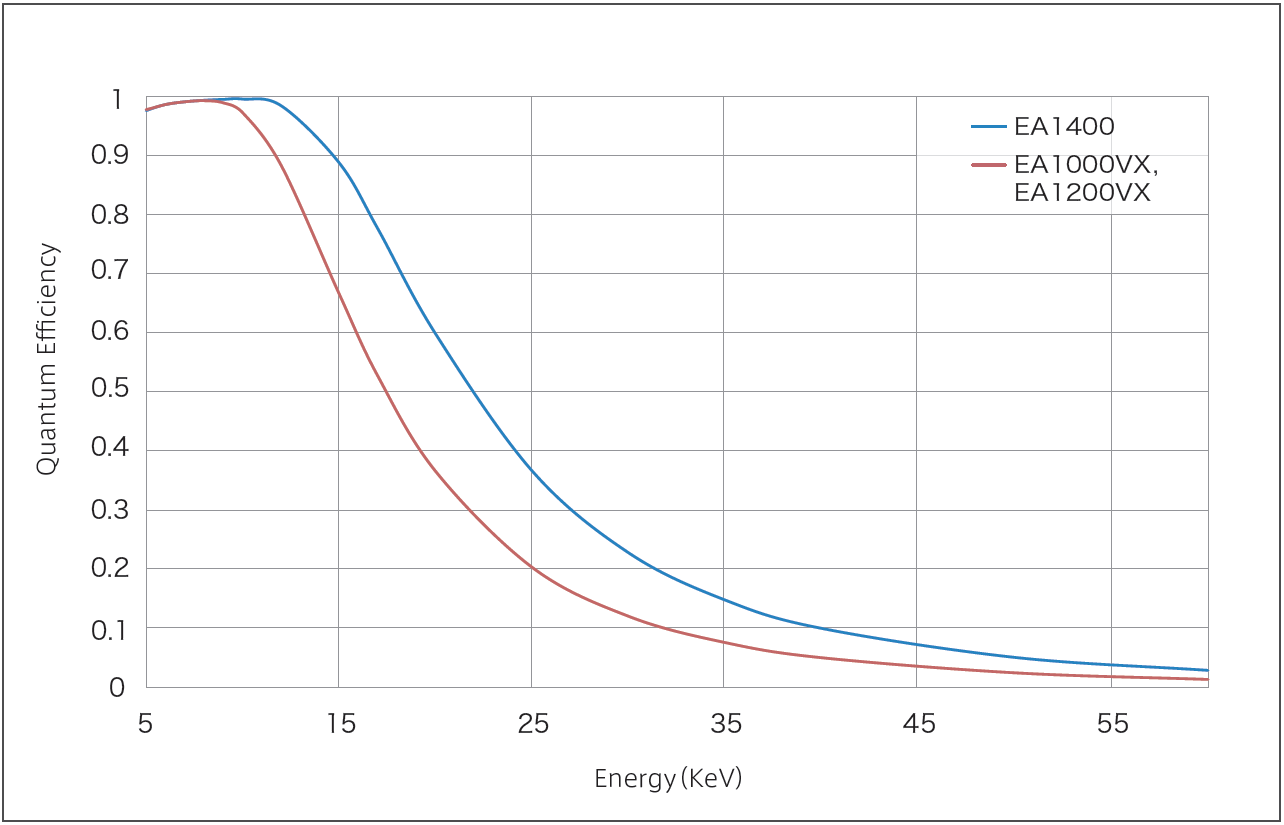

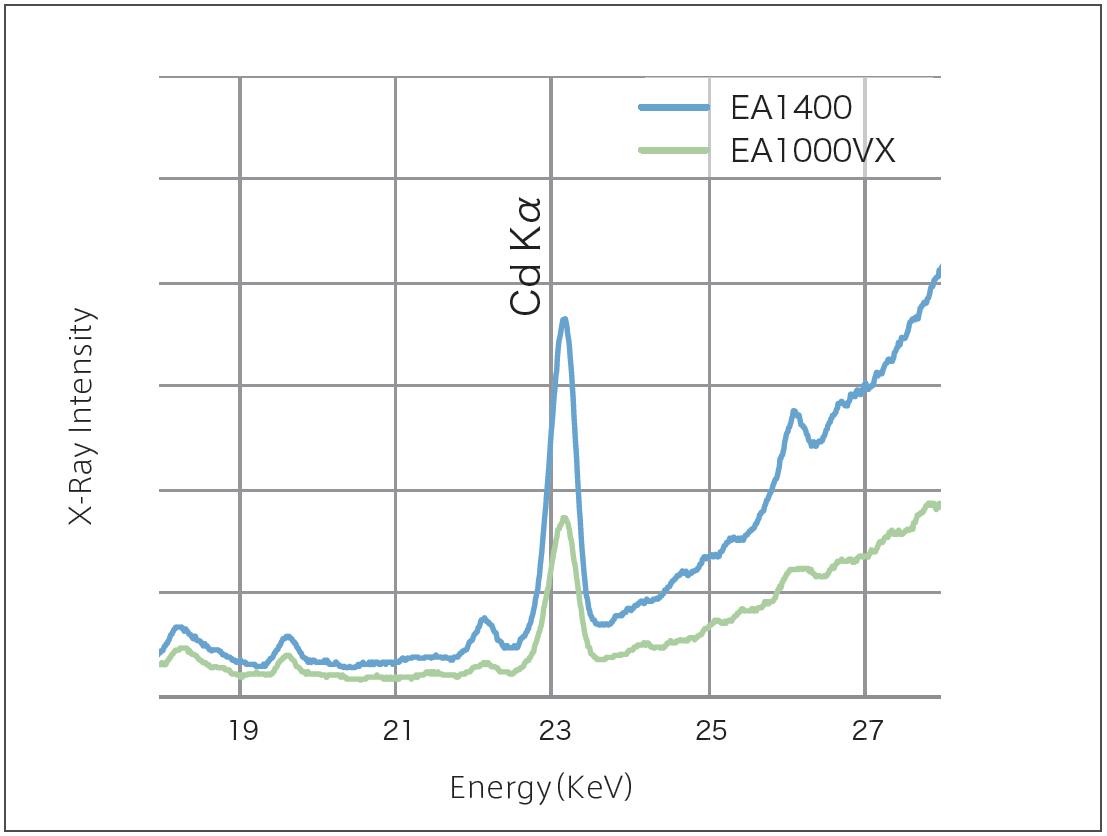

New detector with increased quantum efficiency in the high energy region, making high-sensitivity, high-throughput measurement of the Cd Kα, Pd Kα, Ba Kα energy bands possible.

Higher resolution and higher count rate

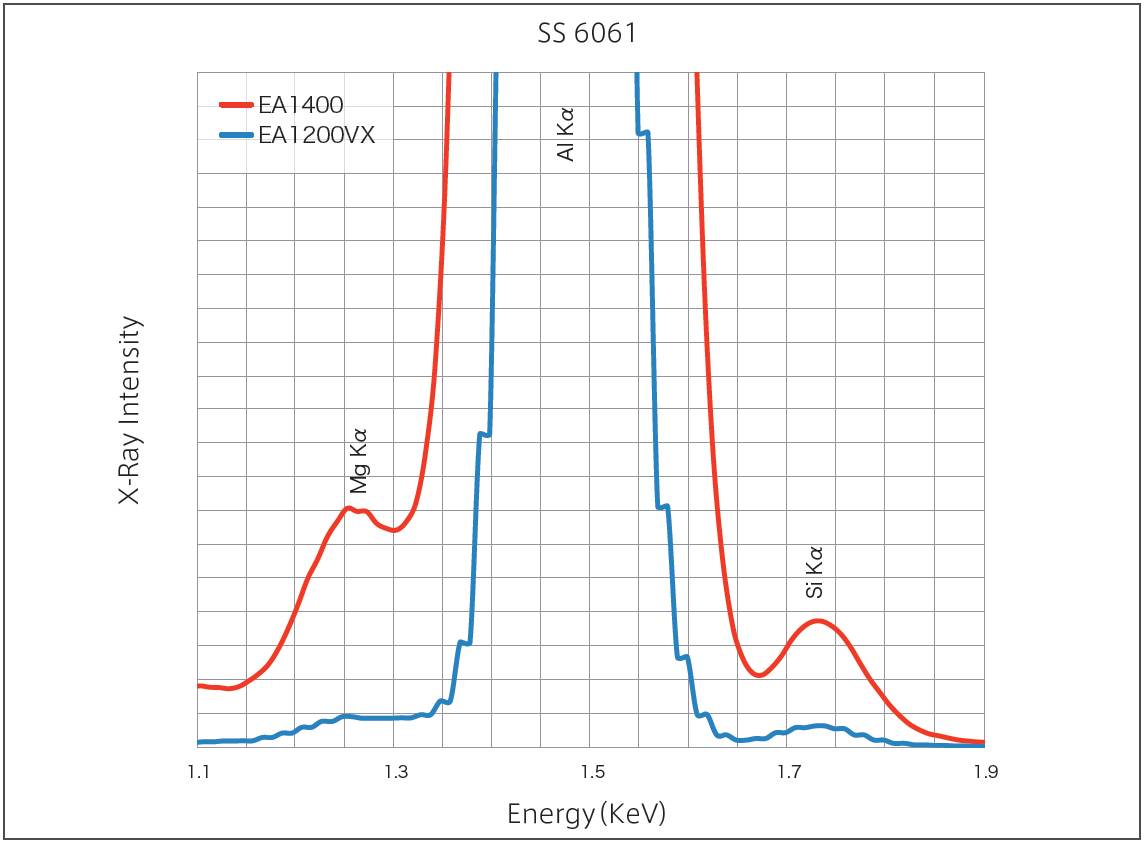

Compared to previous models (EA1200VX [see graph] or EA1000VX) EA1400 excels in detecting trace elements adjacent to the main components of the sample thanks to its high-resolution, high-count rate SDD which allows for exceptional performance in tasks such as quality control of metals and others.

Vacuum System and New SDD

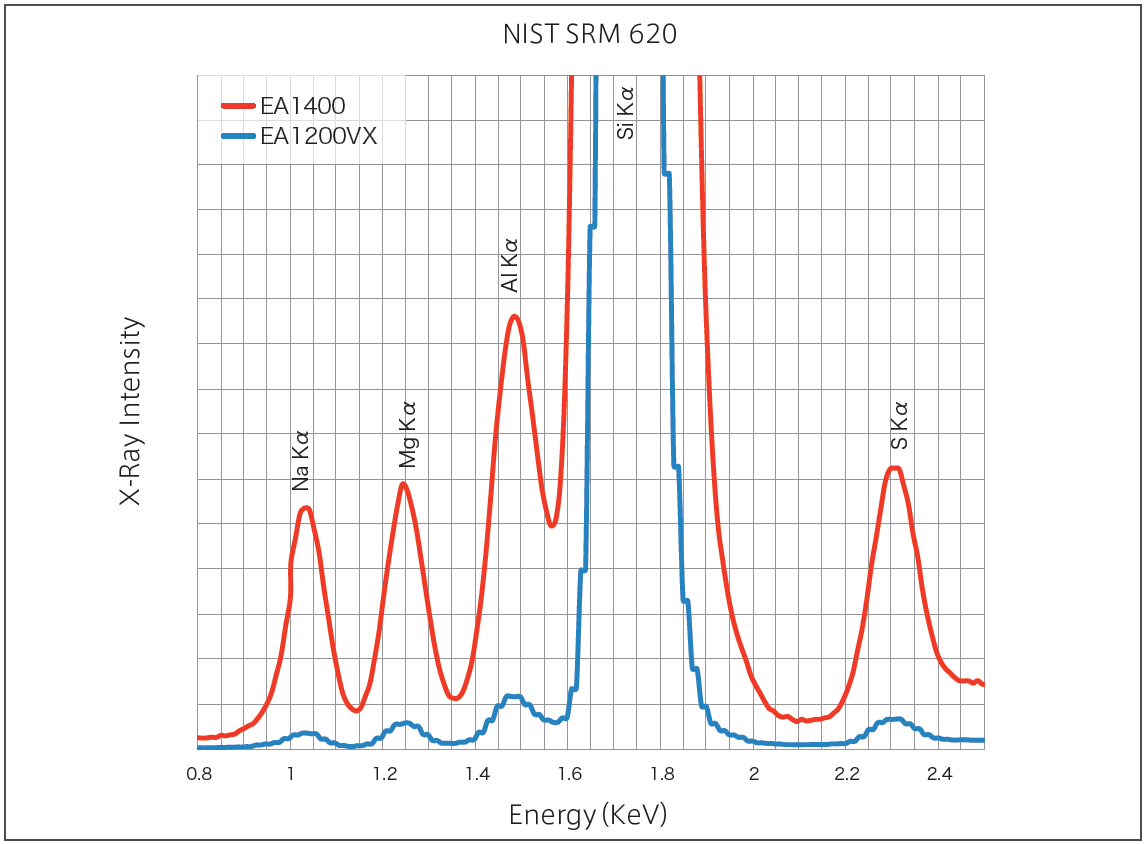

The sensitivity of light elements is greatly improved by using the new detector and vacuum system, which aids in process and quality control of slag and cement.

From RoHS control to an extensive range of areas

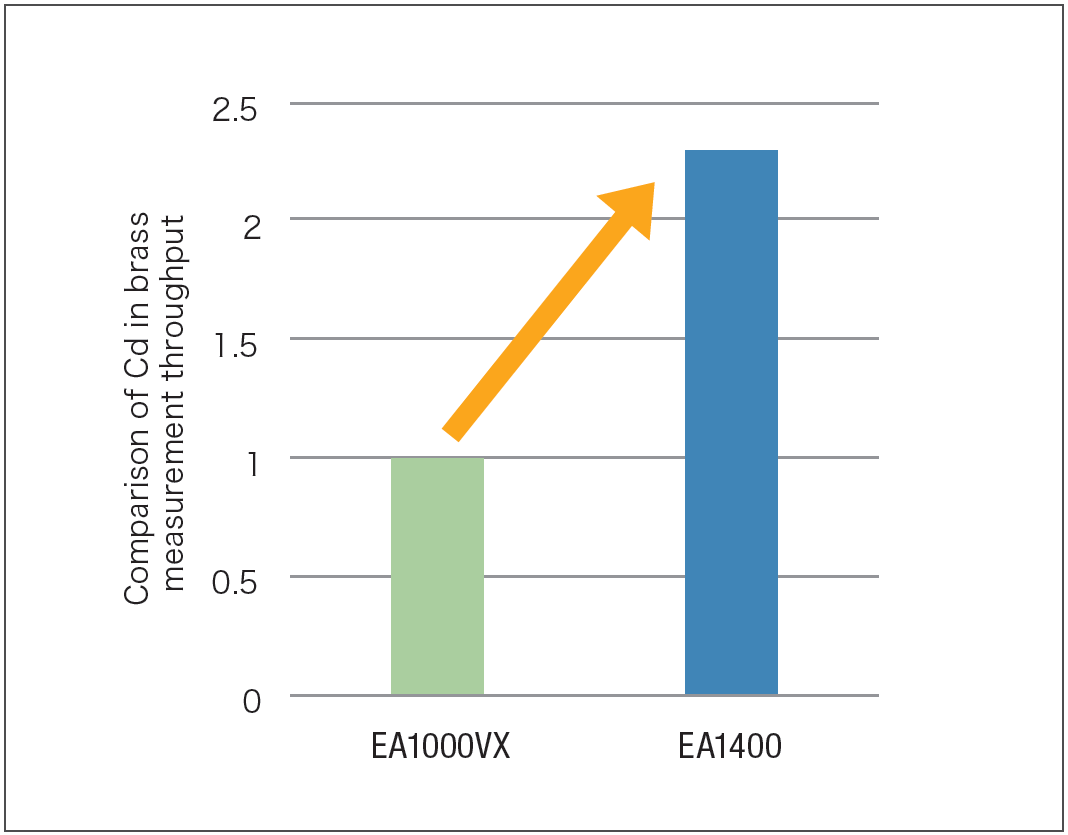

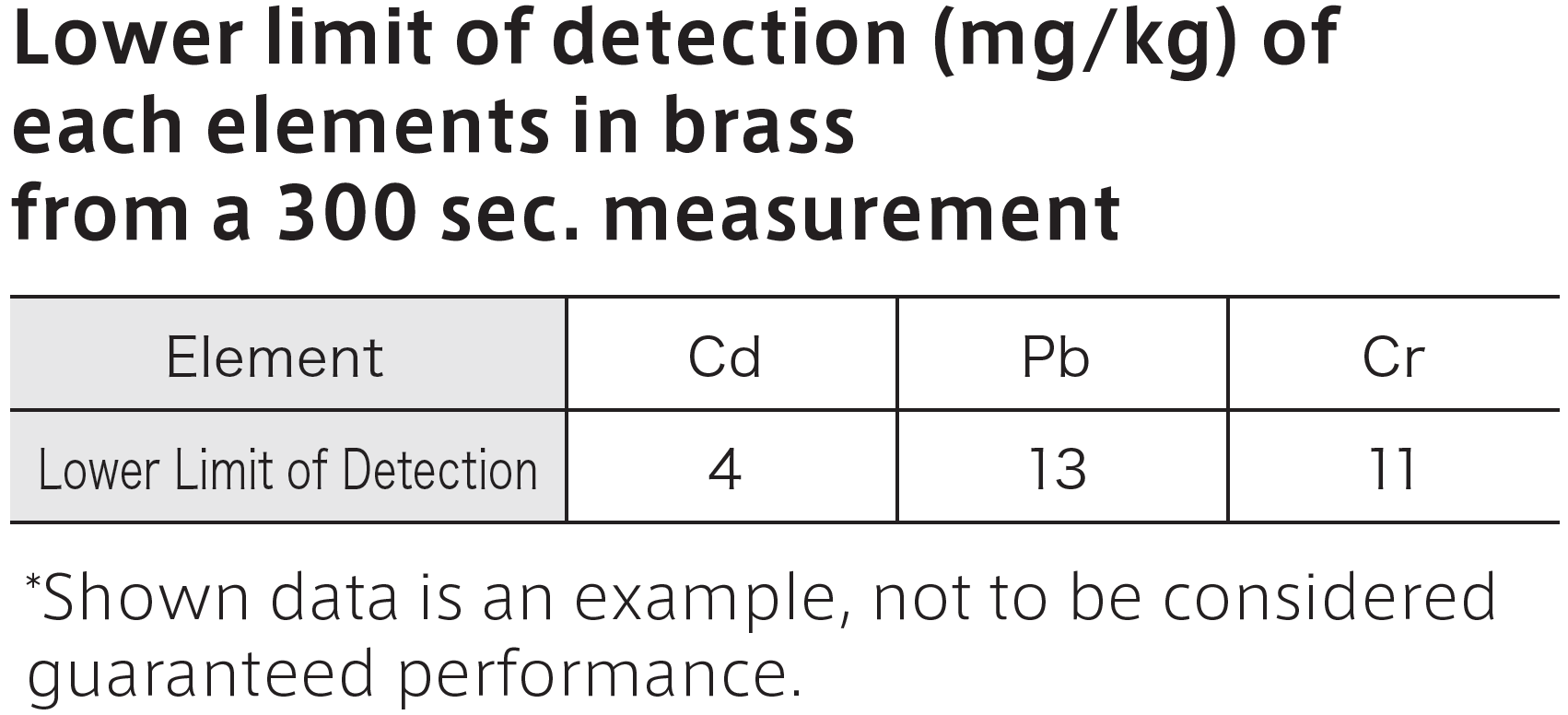

RoHS: Screening of Cd in brass made faster

More than doubled the throughput when measuring traces of Cd in brass and other metals compared to our previous model (EA1000VX.)

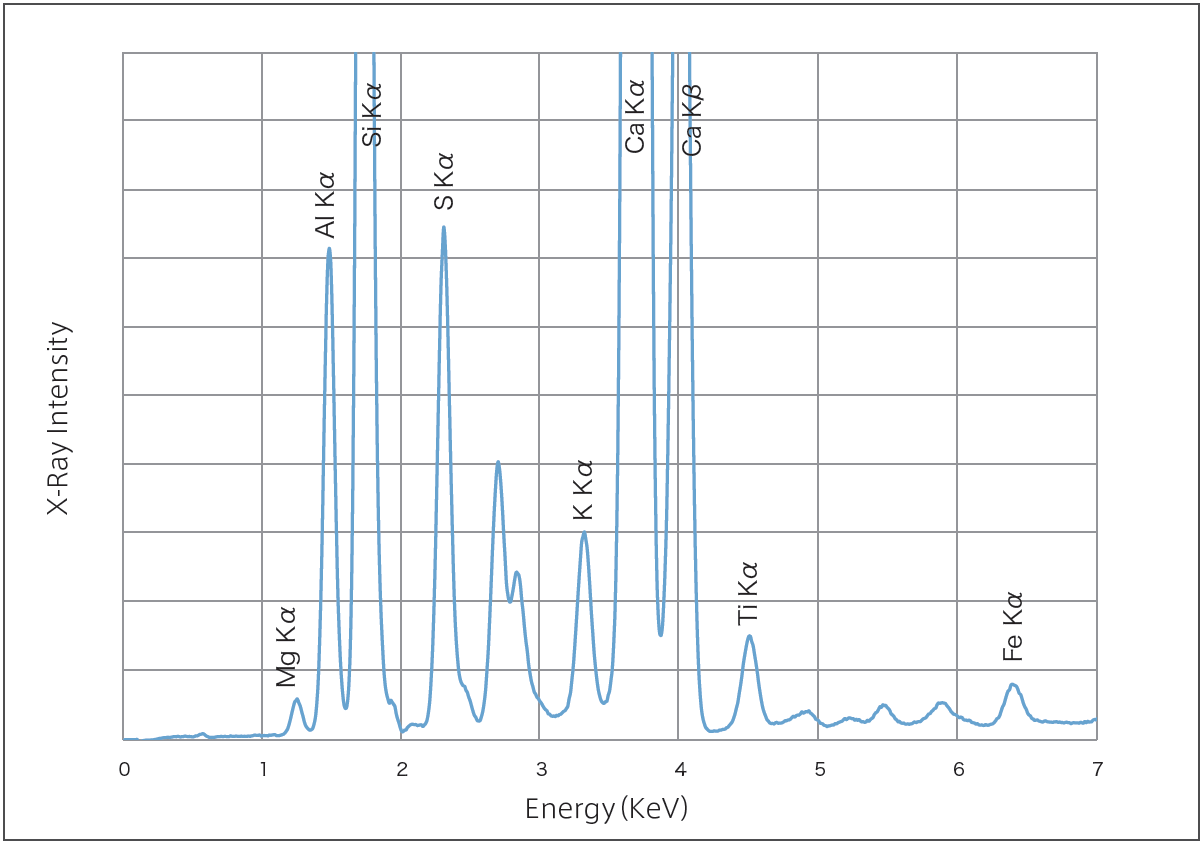

Control process in smelting: fast, accurate measurement of main elements in slag

Smelting process conditions are controlled using the information from slag’s major components; Si, Ca, Al, Mg. The new SDD provides considerable improvement in accuracy with light elements, like Mg, in particular.

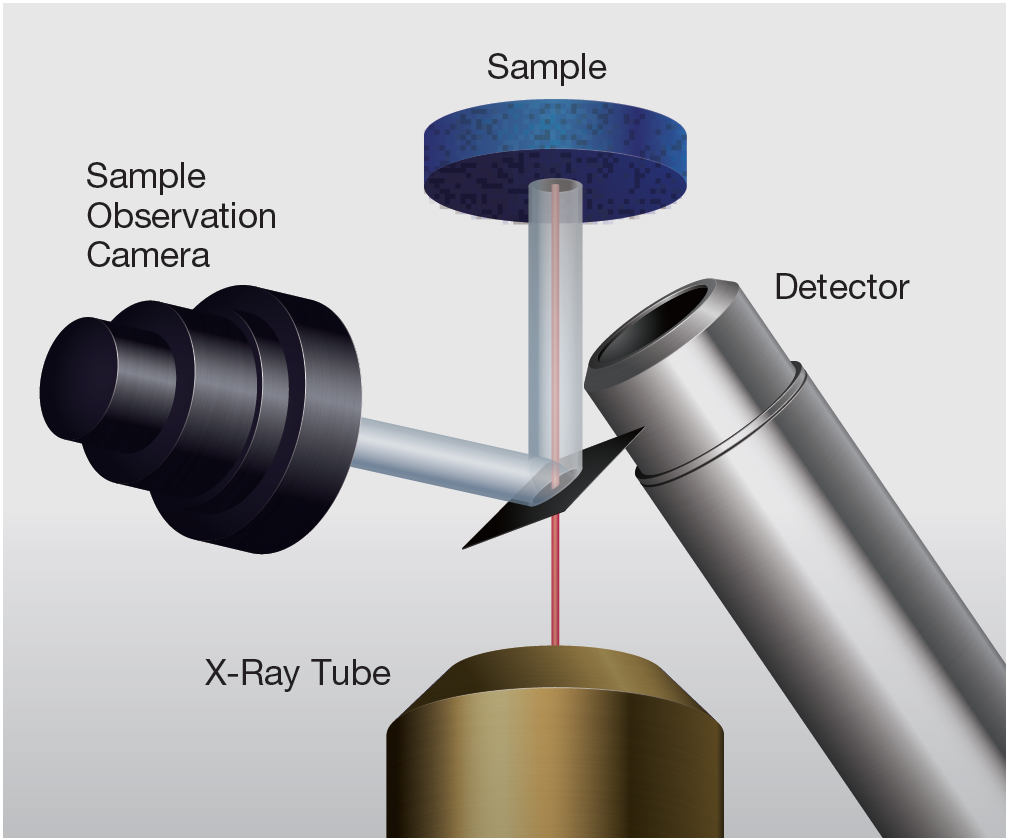

Quality control: detection of adhered, buried foreign matter

With X-ray diagonal irradiation system, it has been difficult to measure samples with uneven or irregular surface and contaminants adhered to the base material. The EA1400, equipped with optimized X-ray irradiation and sample observation mechanism, enables detecting and identifying elements originating from contaminants.

| Item | Specification |

|---|---|

| Origin | Japan |

| Elements | Na(11)~U(92) |

| Sample type | Solid, Powder, Liquid |

| X-ray source | Small Air-cooled x-ray tube (Rh target) |

| Environment | Normal atmosphere (Al~U) Vacuum (Na~U) *Optional |

| X-ray irradiation direction | X-Ray Vertical Irradiation (Coaxial Sample Observation) |

| Detector | Newly developed Silicon Drift Detector (SDD) |

| Measurement Area | 1 mm, 3 mm, 5 mm (automatic switching) |

| Sample imaging | Color CCD camera |

| Filter | 5 mode automatic switching (including OFF) |

| Sample chamber | 304(W)×304(D)×110(H)mm |

| Weight | 69 kg |

| Power requirements | AC100~240V (50/60Hz) / 190VA |

| Sample changer | Compatible (12samples) *Optional |

| Classification | Title | Date |

|---|

LINE

LINE Facebook

Facebook